Address: Unit 19, 54 Fairey Rd, South Windsor NSW 2756

The Critical Importance of Electrical Safety in Commercial & Industrial Settings

Electrical safety is an essential concern in both commercial and industrial settings. These environments often involve complex electrical systems, high-powered machinery, and numerous employees working in close proximity to potentially hazardous equipment. Given these factors, implementing strong safety measures becomes crucial to prevent injuries, protect properties, and ensure the smooth operation of business activities.

In this blog, we’ll explore the critical importance of electrical safety in commercial and industrial settings. By being aware of the electrical hazards and electrical safety measures, businesses can effectively safeguard their workforce and assets while maintaining regulatory compliance and business continuity.

Why Electrical Safety is Crucial in Commercial and Industrial Settings

Electrical safety is crucial in commercial and industrial settings for several reasons:

Prevent Electrical Hazards

Commercial and industrial environments typically have complex electrical systems with high voltages and currents. Improper handling or maintenance can lead to electrical shocks, fires, or explosions which can pose significant risks to workers and property.

Compliance with Regulations

Adhering to electrical safety standards and regulations is mandatory in commercial and industrial settings. Otherwise, non-compliance can result in legal consequences, fines, or even shutdowns, that can impact operations and your business’ reputation.

Protection of Personnel

Electrical safety protects employees from injuries or fatalities caused by electric shocks or electrocution. To guarantee maximum protection, strict adherence to safety protocols should be accompanied by adequate training on electrical hazards as well as equipment maintenance and use of personal protective equipment (PPE).

Preservation of Equipment

Electrical malfunctions can damage expensive machinery, interrupt production, and lead to costly repairs or replacements. Implementing safety measures such as regular inspections and surge protection safeguards equipment.

Fire Prevention

Electrical faults are a common cause of fires in commercial and industrial buildings. Preventative measures like proper wiring, circuit protection, and electrical component maintenance mitigate fire risks and ensure continuity of operations.

Operational Continuity

Unplanned electrical incidents can disrupt business operations, leading to downtime, loss of productivity, and revenue. Investing in electrical safety protocols helps maintain continuous operation and business continuity.

Environmental Safety

Electrical safety also encompasses environmental concerns, as electrical incidents can lead to hazardous material releases or pollution. Mitigating these risks through safety protocols ensures environmental compliance and sustainability.

Types of Electrical Hazards in Commercial and Industrial Spaces

There are several types of electrical hazards in commercial and industrial settings that can pose risks to workers, equipment, and operations. These hazards include:

Electric Shock

Electric shocks occur when the body becomes a path for electrical current. As a result, this can lead to muscle contractions, burns, and, in severe cases, cardiac arrest or death. The severity of the shock depends on factors such as the voltage, current pathway through the body, and duration of exposure.

Faulty Wiring

Faulty wiring can lead to short circuits, power outages, electrical fires, and even electric shocks. That’s why regular inspections and proper maintenance are crucial to identify and rectify faulty wiring issues and prevent potential disruptions and dangers in the commercial or industrial space.

Exposed Live Wires

Temporary installations, such as during construction or renovation projects, often involve makeshift wiring or extension cords. These may not be properly insulated or secured, leading to exposed live wires. If not properly addressed, they can pose serious hazards not only to workers but also to the general public who may come into contact with them accidentally.

Overload and Overcurrent

When electrical circuits are overloaded or when excessive current flows through conductors, it can lead to overheating, damage to equipment, and increased risk of fires. As such, properly designed electrical systems mitigate these risks by making sure circuits are appropriately sized and protected with circuit breakers or fuses.

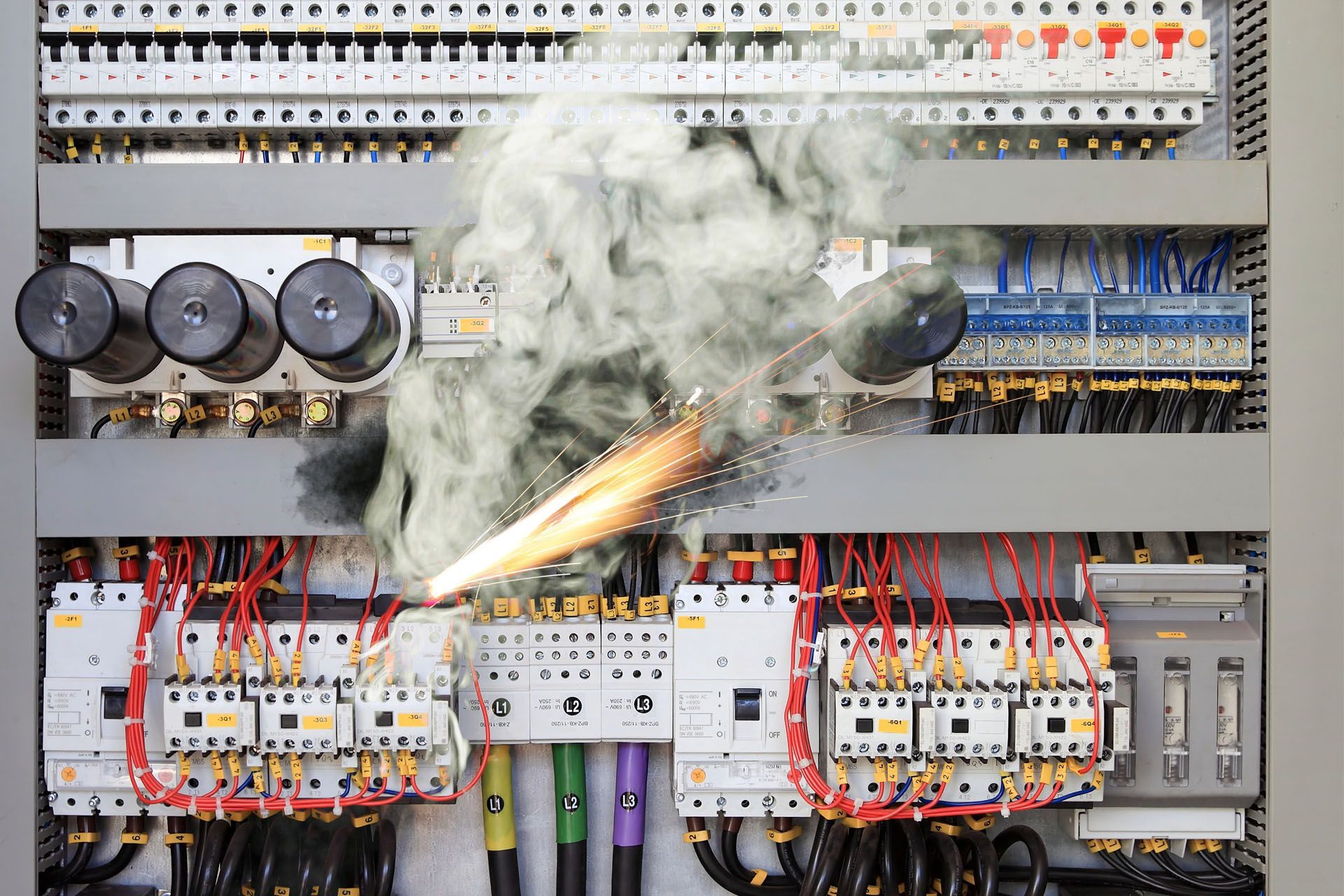

Arc Flash

An arc flash is a sudden release of electrical energy through the air when a high-voltage gap exists and there is a breakdown between conductors. This can result in a highly dangerous explosion that can cause severe burns, blast injuries, and even death to individuals in proximity to the event.

Implementing Electrical Safety Measures in Commercial and Industrial Facilities

Here are some key electrical safety measures that should be implemented by an industrial and commercial electrician.

Regular Inspections and Maintenance

Conducting regular inspections and maintenance of electrical systems and equipment is crucial. This includes checking for:

- Worn or damaged wiring

- Faulty connections

- Signs of overheating

- Proper functioning of safety devices like circuit breakers and fuses

Safety Standards and Compliance

Adhering to the electrical safety standards, such as those set by the

Electrical Regulatory Authorities Council (ERAC) in Australia is mandatory. These standards make sure that all electrical work is conducted safely and in accordance with established guidelines to protect workers from electrical hazards.

Training and Awareness

Making sure that all employees are aware of electrical safety protocols is vital. Hence, training should cover:

- Recognising electrical hazards

- Proper use of electrical equipment

- Emergency response procedures

- Lockout/tagout (LOTO) procedures

Personal Protective Equipment (PPE)

Providing appropriate PPE for employees working with or around electrical systems is essential. This may include:

- Insulated gloves and tools

- Arc-rated clothing

- Safety goggles and face shields

- Hearing protection for noisy environments

Emergency Preparedness

Having a well-defined emergency response plan can save lives and minimise damage in the event of an electrical incident. This should include:

- Clear evacuation routes

- Emergency contact information

- First aid procedures

- Regular drills to promote readiness

Conclusion

Prioritising electrical safety in commercial and industrial settings is essential to keep employees safe, maintain operations, and prevent costly downtime. However, to achieve these goals effectively, it is important to implement strong safety management systems, conduct thorough risk assessments, and consistently update procedures in accordance with industry standards and regulatory requirements. Significantly, promoting a culture of safety awareness among all personnel further strengthens the commitment to maintaining a safe workplace.

Need an industrial and commercial electrician in Western Sydney? Ronika has got you covered. We service clients in Windsor, Riverstone, Hills District, Hawkesbury, Penrith, Hornsby, Richmond, and Blacktown City. Get in touch to get started.